1 Fossil Fuel Technology

Noah Mervak

1.1 Introduction

Keywords

- Fossil fuel – a natural fuel such as coal or gas, formed in the geological past from the

remains of living organisms. - Energy grid – an interconnected network for electricity delivery from producers to consumers.

- Coal – a combustible black or brownish-black sedimentary rock with a high amount of carbon and hydrocarbons.

- Power plant – an industrial facility that generates electricity from primary energy.

- Natural gas – a naturally occurring hydrocarbon gas mixture which consists of methane, other higher alkanes, and sometimes a small amount of carbon dioxide, nitrogen, hydrogen sulfide, or helium.

- Boiler – a fuel-burning apparatus or container for heating water.

- Steam turbine – a turbine in which a high-velocity jet of steam rotates a bladed disk or drum.

- Generator – a dynamo or similar machine for converting mechanical energy into electricity.

- Syngas – a fuel gas mixture consisting mostly of hydrogen and carbon monoxide.

- Gas turbine – a turbine driven by expanding hot gases produced by burning fuel, as in a jet

engine. - Thermal efficiency – the efficiency of a heat engine measured by the ratio of the work done by it to the heat supplied to it.

- Economizer – mechanical devices intended to reduce energy consumption, or to perform useful functions such as preheating a fluid.

- Fuel cell – a cell producing an electric current directly from a chemical reaction.

- Greenhouse gas – a gas that contributes to the greenhouse effect by absorbing infrared

radiation, e.g., carbon dioxide and chlorofluorocarbons. - Hydraulic fracturing – the forcing open of fissures in subterranean rocks by introducing liquid at high pressure, especially to extract oil or gas.

Learning Objectives

By the end of this chapter, students should be able to:

- Compare and contrast coal-fired PCC, HELE, and IGCC power plants

- Compare and contrast simple cycle and combined cycle natural gas-fired power plants

- Understand the origins of coal-fired and natural gas-fired power plant technologies

- Explain how fossil fuels positively and negatively affect society and environment

- Consider the future outlook of fossil fuels

How often do you turn on your lights, charge your phone, store food in your refrigerator, send an email, set your thermostat, perhaps often? While we may take all of these things for granted, they all require electricity primarily produced by fossil fuel technology which has been powering the world’s machines and appliances since the industrial revolution. As global electricity demand increases, fossil fuel technology has adapted to increase power output, efficiency, and improve emissions control. In a carbon-constrained climate however, where our carbon footprint must be minimized, the future outlook of fossil fuels is uncertain. With their ‘dirty’ combustion, fossil fuel technologies must innovate to reduce pollution or support our transition to renewable energy generation.

1.2 What is Fossil Fuel Technology?

Key Takeaway

1.2.1 Coal Fired Power Plants

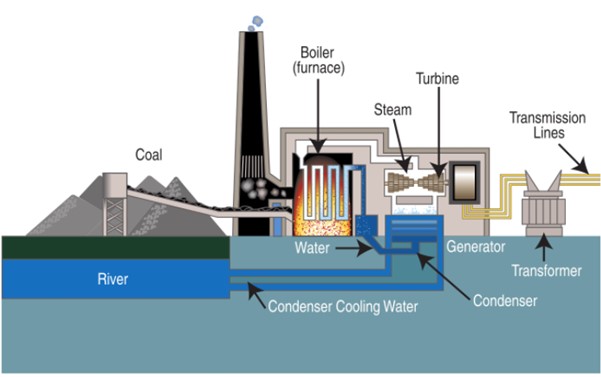

As its name implies, coal fired power plants produce electricity using coal as fuel. Conventional coal plants use a pulverized coal combustion (PCC) system where coal is pulverized to increase surface area and allow it to burn more rapidly (WCA, 2021). This pulverized coal is burned in a boiler to produce steam. This steam, subjected to immense pressure, flows into a steam turbine, which spins a generator to produce electricity. The steam is then cooled, condensed back into water, and returned to the boiler to start the process again (TVA, 2021).

“Coal-fired plant” by Tennessee Valley Authority is in the Public Domain.

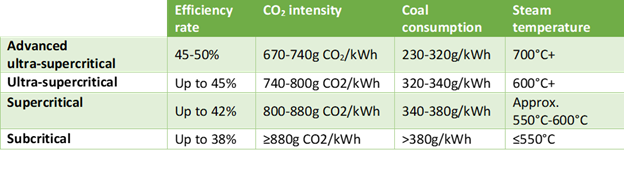

There are also more advanced coal fired power plants such as High Efficiency Low Emissions (HELE) plants which operate similarly to PCC plants; however, HELE plants operate at higher temperatures and pressures. This increases the overall efficiency of the plant meaning that less coal will produce more electricity. There are three types of HELE plants: Supercritical, Ultra-Supercritical, and Advanced Ultra-Supercritical (WCA, 2021).

Adapted from IEA, Technology roadmap: High-efficiency, low-emissions coal-fired power generation, 2012.

The downside to HELE technology is the higher capital costs compared to PCC (subcritical) plants. This is due to the material construction of the HELE plant components and specialty welding to combat the higher temperature and pressures. These higher costs may be partially offset by fuel savings (IEA, 2012).

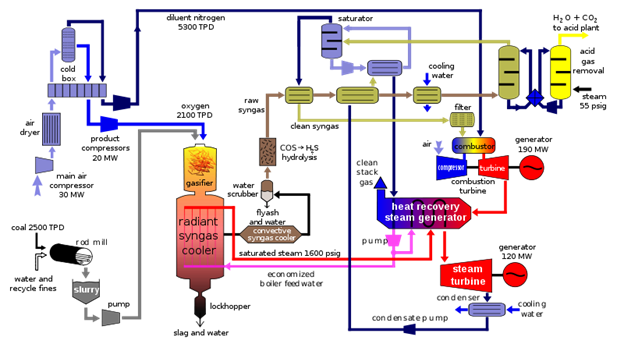

The most recent advancement in coal technology is called the Integrated Gasification Combined Cycle (IGCC). IGCC systems do not combust coal directly. Instead, coal is reacted with oxygen and steam to produce a syngas composed mainly of hydrogen and carbon monoxide. This syngas is then cleaned of impurities and burnt in a gas turbine to generate electricity. The hot exhaust gas of the gas turbine is then used to raise steam in a heat recovery steam generator (HRSG) for a steam power cycle, producing even more electricity. (IEA, 2012, WCA, 2021).

“IGCC diagram” by Stan Zurek is licensed under CC BY-SA 3.0

1.2.2 Natural Gas Fired Power Plants

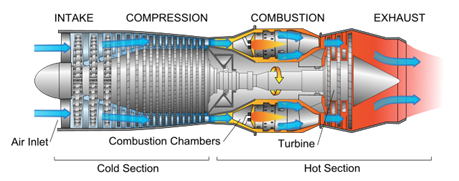

Natural gas fired power plants use natural gas as fuel to produce electricity. Natural gas is added, along with a stream of air, which combusts and flows through a gas turbine. This causes the generator to spin a magnet, making electricity.

“Jet Engine” by Jeff Dahl is licensed under CC BY-SA 4.0.

There are two types of natural gas power plants: simple cycle gas plants and combined cycle gas plants. Simple cycle gas plants are less efficient than the combined cycle. However, simple cycle plants dispatch faster. In other words, simple cycle plants may be turned on and off quicker than combined cycle plants and even coal or nuclear power plants. This makes them excellent for meeting the fluctuating electricity needs of society, known as peaking hour. They are also often needed on the energy grid with wind power and solar power for supplementary electricity production (J.M.K.C. Donev et al., 2019).

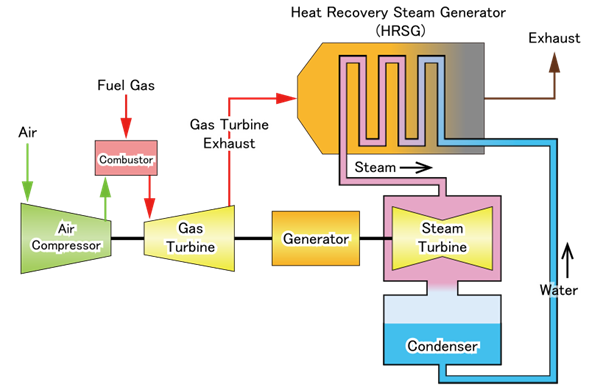

Combined cycle gas plants have both a gas and steam turbine. This is because a combined cycle gas plant is a simple cycle gas plant combined with a HRSG (similar to a IGCC plant) . The simple cycle operates the same as previously explained, however the waste heat of this cycle is captured and sent to a HRSG to raise steam and produce electricity using a steam turbine (J.M.K.C. Donev et al., 2019). This makes combined cycle gas plants more efficient than simple cycle gas plants.

“Gas Turbine Combined Cycle Generation” by Σ64 is licensed under CC BY 4.0.

1.3 The History of Fossil Fuel Technology

Key Takeaway

1.3.1 Coal and the Steam Turbine

The first steam turbine was invented by Sir Charles Parsons in 1884. This turbine would only have a thermal efficiency of 1.6%. By the early 1900s, coal-fired power units provided an output range of 1 MW to 10 MW. These units included a steam generator, an economizer, evaporator, and a superheater section. With the introduction of turbines with steam extractions for feedwater heating and steam generators equipped with air preheaters, the net efficiency of the coal-fired power plants was increased to about 15% (Power, 2020).

In 1919, pulverized coal steam generators were demonstrated at the Oneida Street Station in Wisconsin. This vastly improved coal combustion and allowed for bigger boilers.

“Oneida Street Station May09” by Freekee is in the Public Domain.

The advent of the once-through boiler applications, reheat steam power plants, and Benson steam generator in the 1920s ensured that they would become the norm in the 1930s as unit ratings soared to a 300-MW output level. Advancements in coal technology from 1940 to 1960 consisted mostly of efficiency improvements and the construction of the first once-through steam generator with a supercritical main steam pressure. Unit ratings of 1,300 MW were reached by the 1970s and the first IGCC plant was constructed in 1972 with an output of 183 MW. Scrubbers were also beginning to be implemented to mitigate sulfur dioxide emissions. The 1980s to present brought further advancements in emissions control technologies including selective catalytic reduction systems as well as carbon capture and storage systems (Power, 2020).

1.3.2 Natural Gas and the Gas Turbine

During World War II, GE engineers were developing jet engine technology. After World War II, these GE engineers decided to focus their knowledge and design a gas turbine for industrial and utility services. This led to the construction of the first commercial gas turbine for power generation (3.5 MW) at the Belle Isle Station in July, 1949. This power station may also be considered the first ever combined cycle power plant as the unit used exhaust heat for feedwater heating of a steam turbine unit. Improvements in gas turbine technology in the 1950s were characterized by higher firing temperatures (1,300°F to 2,000°F) and the installment of the first HRSG for a gas turbine in 1957. In 1965, the first fully fired boiler combined cycle gas turbine (CCGT) power plant came online and was fitted with a HRSG by 1968. Meanwhile (1960s), gas turbine suppliers began developing standard CCGT plants. For example, GE developed the STAG (steam and gas) system, Westinghouse, the PACE (power at combined efficiency) system, and Siemens, the GUD (gas and steam) system (Power, 2020).

“Jiangsu Huadian Wangting Power Station” by Bjoertvedt is licensed under CC BY-SA 4.0.

More recently, the first advanced gas turbines were introduced in 1990 and the installment of the first CCGT with a fuel cell in 2000 (Power, 2021).

1.4 Impact of Fossil Fuel Technology on Society

Key Takeaway

1.4.1 Pros of the technology

Coal and natural gas power plants have given us easy and consistent access to electricity which has become a fundamental utility in the United States. Coal fired power plants allowed for the expansion of the industrial revolution while natural gas fired power plants took up the mantle to provide electricity with 50-60% less carbon dioxide emissions. The flexibility of natural gas with its simple cycle gas plants also makes it a good partner for variable renewable energy sources such as wind and solar (Gasvessel, 2021).

1.4.2 Cons of technology

Coal-fired power plants emit greenhouse gases (GHG) into the earth’s atmosphere as well as other toxic waste products. When coal is burned, it releases several airborne toxins and pollutants which include mercury, lead, sulfur dioxide, nitrogen oxides, particulates, and various other heavy metals. These waste products may pollute the air, contribute to climate change, or contaminate waterways and drinking water supplies (UCS, 2019). The mining of coal also has a significant impact on the environment such as erosion, habitat destruction, and acid mine drainage (WWF, 2020).

Natural gas-fired power plants also emit GHGs; however, at much lower rates than coal-fired power plants. The combustion of natural gas produces 50-60% less carbon dioxide than coal combustion and produces negligible amounts of sulfur, mercury, and particulates (Gasvessel, 2021). This means that natural gas burns much cleaner than coal and may be considered the cleanest fossil fuel. The extraction of natural gas, however, is not as environmentally friendly. Drilling a well may affect local ecosystems, migration patterns, and water quality. Hydraulic fracturing (fracking) may cause earthquakes and overburden local water sources (MET, 2021).

“CREDO Action & New Yorkers Against Fracking Protest Gov. Cuomo’s Plan to Frack New York” by CREDO is licensed under CC BY 2.0

1.5 Future Outlook

Key Takeaway

Due to coal and natural gas’s negative environmental impacts and their contribution to climate change, they will be phased out in favor of more eco-friendly energy sources.

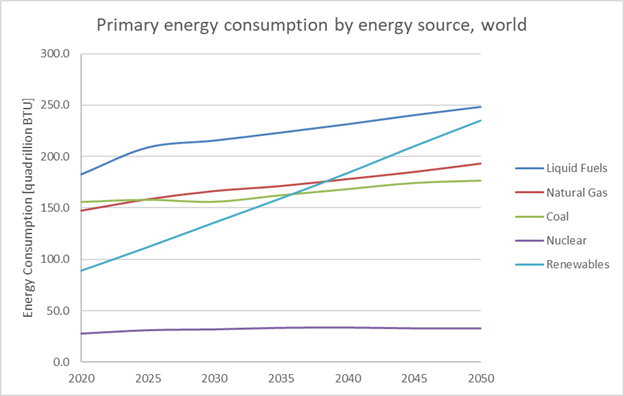

Adapted from U.S. Energy Information Administration, International Energy Outlook 2021 (IEO2021).

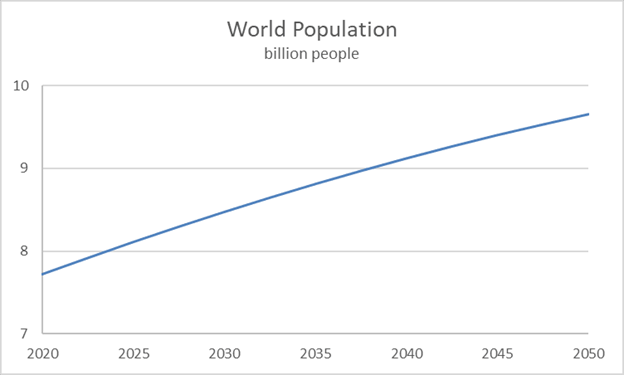

Based on Figure 1.8 (above), natural gas energy consumption should surpass coal in 2025 while renewables should surpass both coal and natural gas between 2035 and 2040. Notice that this future outlook does not show a decrease in any one energy source. This may be because over time, energy consumption increases as populations increase and countries become more developed. In other words, legacy energy sources may continue to be used while renewable energy production is increased to meet growing electricity demand due to growing populations and societal needs in the future.

Adapted from U.S. Energy Information Administration, International Energy Outlook 2021 (IEO2021).

Dominion Energy Inc. is making big changes in South Carolina after its acquisition of SCANA Corp. in 2019. In 2020, the Public Service Commission of South Carolina, according to S&P Global, sent a directive to Dominion Energy South Carolina (DESC) saying:

Dominion is required to update its planning assumption relating to the energy and demand forecast, commodity fuel price inputs, renewable energy forecast, energy efficiency and demand-side management forecasts, and changes to projected retirement dates of existing units in its modified 2020 (integrated resource plan) IRP and in future IRPs. (S&P Global, 2021)

Out of 14 different generation plans DESC considered, “Resource Plan 8” is the favored option. Under this plan, Dominion Energy would retire the 684 MW Wateree coal plant and the 610 MW Williams coal plant. This plan would also convert the 415 MW dual-fired Cope power plant to run solely on natural gas in 2030. These plants would be replaced by a 553 MW combined-cycle gas plant and a 523 MW simple cycle gas plant in 2028. This plan also calls for a further addition of 400 MW of natural gas capacity before 2041. These additions would protect the reliability of 1,900-2,000 MW of solar and 700-900 MW of battery storage to be installed from 2026 to 2048 (S&P Global, 2021).

Chapter Summary

Fossil fuel technology has given us the capability to produce electric power for our society. Using coal and natural gas, power plants fueled the industrial revolution and continue to power the world’s innovation. And with the constant increase in consumer demand for electricity, fossil fuel technology may be there to supply it. However, coal and natural gas do not come without costs. These fuels are harmful to the environment, contributing to climate change, habitat destruction, and pollution. In a carbon-constrained future, fossil fuel technologies will either need to adapt or be phased out in favor of renewable energy.

Review Questions

- Which of the following systems is the most efficient?

A. Ultra-supercritical

B. Subcritical

C. Advanced Ultra-supercritical

D. Supercritical - What pollutants are released due to coal combustion? (select all that apply)

A. Helium

B. Sulfur Dioxide

C. Lead

D. Mercury - Which system is a type of gas-fired power plant?

A. Combined Cycle

B. PCC

C. HELE

D. IGCC - What are HRSGs used for?

A. Aid in the gasification of coal in IGCC plants

B. To increase plant efficiency and produce more electricity

C. To condense steam

D. To send steam to a gas turbine

Answers:

- C

- B, C, D

- A

- B

Food for Thought

1. What do you think the future holds for fossil fuels? Do you agree with the future outlook of primary energy consumption according to the EIA’s IEO2021 report?

2. What would be your version of a “just transition” from fossil fuels to renewable energy? Consider job loss/gain and regional wealth patterns.

3. What may our world look like today without our advancements in fossil fuel technology?

References

Coal & Electricity. World Coal Association. (2021, October 29). Retrieved November 21, 2021,

from https://www.worldcoal.org/coal-facts/coal-electricity/#efficiency-improvements.

Coal Power Impacts. Union of Concerned Scientists. (2019, July 9). Retrieved November 21,

2021, from https://www.ucsusa.org/resources/coal-power-impacts.

Coal. WWF. (2020). Retrieved November 21, 2021, from https://wwf.panda.org/discover/knowledge_hub/teacher_resources/webfieldtrips/climate_change/coal/.

History of power: The evolution of the electric generation industry. POWER Magazine. (2020,

December 23). Retrieved November 21, 2021, from https://www.powermag.com/history-of-power-the-evolution-of-the-electric-generation-industry/.

How a Coal Plant Works. Tennessee Valley Authority. (2021). Retrieved November 21, 2021, from

https://www.tva.com/Energy/Our-Power-System/Coal/How-a-Coal-Plant-Works.

J.M.K.C. Donev et al. (2019). Energy Education – Natural gas power plant [Online]. Available:

https://energyeducation.ca/encyclopedia/Natural_gas_power_plant#cite_note-8. [Accessed: November 17, 2021].

Natural Gas Environmental Impact: Problems and Benefits. MET. (2021). Retrieved November

21, 2021, from https://group.met.com/fyouture/natural-gas-environmental-impact/64.

Natural gas vs. coal – a positive impact on the environment. GASVESSEL. (2018, September

19). Retrieved November 21, 2021, from https://www.gasvessel.eu/news/natural-gas-vs-coal-impact-on-the-environment/.

Sweeney, D. (2021, February 23). Dominion files plan to shut down SC Coal Fleet, replace with gas, Solar. S&P Global Marketplace Intelligence. Retrieved November 21, 2021, from https://www.spglobal.com/marketintelligence/en/news-insights/latest-news headlines/dominion-files-plan-to-shut-down-sc-coal-fleet-replace-with-gas-solar-62812013.

Tsai, J.-H., Chen, S.-H., Chen, S.-F., & Chiang, H.-L. (2021, September 10). Air pollutant emission abatement of the fossil-fuel power plants by multiple control strategies in Taiwan. MDPI. Retrieved November 21, 2021, from https://www.mdpi.com/1996-1073/14/18/5716/html.

A natural fuel such as coal or gas, formed in the geological past from the remains of living organisms.

A combustible black or brownish-black sedimentary rock with a high amount of carbon and hydrocarbons.

An industrial facility that generates electricity from primary energy.

A fuel-burning apparatus or container for heating water.

A turbine in which a high-velocity jet of steam rotates a bladed disk or drum.

A dynamo or similar machine for converting mechanical energy into electricity.

A fuel gas mixture consisting mostly of hydrogen and carbon monoxide.

A turbine driven by expanding hot gases produced by burning fuel, as in a jet

engine.

A naturally occurring hydrocarbon gas mixture which consists of methane, other higher alkanes, and sometimes a small amount of carbon dioxide, nitrogen, hydrogen sulfide, or helium.

An interconnected network for electricity delivery from producers to consumers

The efficiency of a heat engine measured by the ratio of the work done by it to the heat supplied to it.

Mechanical devices intended to reduce energy consumption, or to perform useful functions such as preheating a fluid.

A cell producing an electric current directly from a chemical reaction.

A gas that contributes to the greenhouse effect by absorbing infrared radiation, e.g., carbon dioxide and chlorofluorocarbons.

The forcing open of fissures in subterranean rocks by introducing liquid at high pressure, especially to extract oil or gas.